In the realm of manufacturing, precision is extremely important. Whether it’s for creating intricate internal shapes or ensuring smooth lubrication and airflow, the techniques of Wire EDM and ED (Electrical Discharge) Drilling have revolutionized the process of crafting through-holes with accuracy and finesse.

EDM stands for Electrical Discharge Machining which is a specialized technique used to shape metal parts with electrical sparks. Now, imagine shrinking that process down to create small holes. That’s the essence of EDM micro hole drilling.

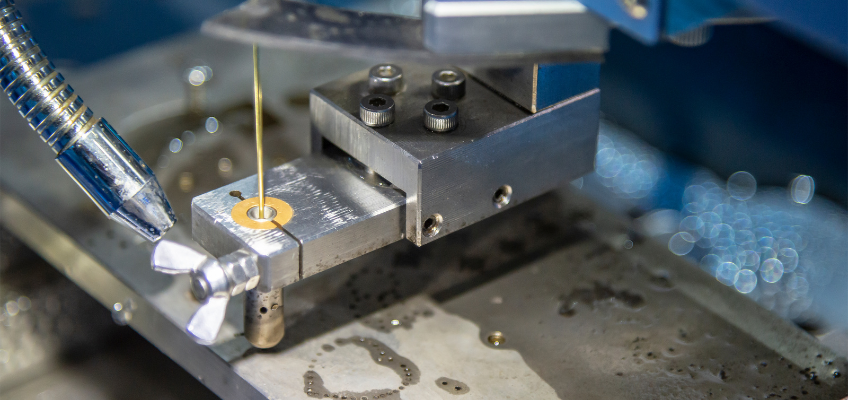

So how does it work? Typically, there’s a small electrode and a workpiece submerged in a dielectric fluid such as water. When an electrical current passes between the electrode and the workpiece, tiny sparks occur, eroding the material and forming a hole. The process can create holes as small as a fraction of a millimeter in diameter.

Through-Holes

Through-holes play an important role in various applications, from facilitating lubrication in mechanical components to enabling airflow in intricate designs. However, achieving the perfect through-hole involves more than just drilling an opening through a piece of metal; it requires precision and attention to detail.

Enter ED Drilling. Unlike traditional drilling methods, ED drilling is a process where an electrode burns through the material, creating a hole. But there is a catch: as the electrode wears down, the hole can become tapered, and overburn can result in inconsistencies.

Precision Partners: Wire EDM and ED Drilling

This is where Wire EDM steps in. By combining Wire EDM with ED Drilling, manufacturers can achieve both a good finish and precise sizing, even with smaller holes. Wire EDM provides the finesse needed to refine the rough edges left by ED Drilling, resulting in accurate and polished through-holes.

However, it’s essential to note that ED Drilling isn’t without its quirks. The smaller the hole or the taller the part, the less accurate it becomes. Think of it like using a drill bit – the electrode can flex and wander, leading to potential deviations in the hole’s placement or size.

And due to the nuances of ED Drilling, not every job is suitable for this technique. Manufacturers need to assess each project individually to determine its feasibility. It’s a case-by-case basis where factors like hole size, part geometry, and precision requirements are carefully considered.

Electrical Discharge Drilling: A Reliable Solution

For complex internal shapes or delicate components, where traditional drilling might pose a risk of breakage, ED Drilling shines. Customers can simply mark the holes they need, and the worry of snapping a bit becomes a thing of the past. Even if a bit were to break, ED Drilling can seamlessly erase its existence, showcasing the versatility of the technique.

While each technique has its strengths and quirks, together, they offer a comprehensive solution for achieving accuracy and finesse in every project.

Here at CAM Tech, we have designers and engineers who are trained and experienced in ED Drilling with high precision, strength, and durability, so they can maximize Wire EDM’s great potential for your next project.

Contact us at CAM Tech, Inc. We are happy to discuss your project and demonstrate how Wire EDM can benefit your manufacturing requirements.