Wire EDM helped transform and continues to play an important role in today’s mold making technology. Using high-speed cutting machines to achieve sophisticated and potentially complex mold profiles has increased the accuracy and quality of mold production compared to prior methods.

This efficiency has improved mold components such as those for generators, programming systems, drives, flashings, and other facets like filters and fluids, wires, electrodes, and graphite. And through wire EDM, mold makers were able to achieve precision components with great degrees of accuracy and quality finish.

How Does It Work?

Wire EDM is mostly used to cut out mold components that require complex shapes and precise holes, and those that utilize tougher types of materials such as carbide and steel. In mold making, the profile, shape, and cut out processes are important.

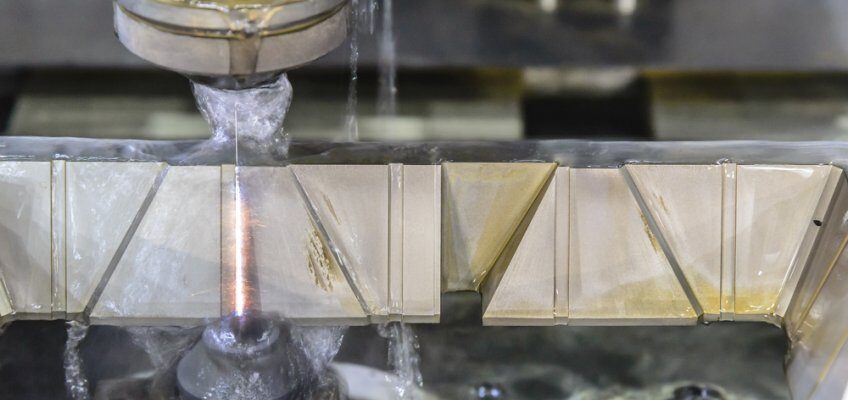

Wire EDM works on the manufacturing of mold components by electro-erosion where conductive materials are removed by spark eroding. This is made by pulse discharges between the wire as the electrode and the conductive piece that is being worked on. Both of these are submerged in deionized water.

Creating narrow slits and cut sheets, special-shaped holes, and templates are cut quickly and accurately with wire EDM. Mold components that are produced with wire EDM can be used directly from production, even without polishing, due to the high cutting precision.

Wire EDM for Mold Components

Of course, to ensure precision of the mold, a wire EDM machine is not enough. You also need an experienced engineer to handle the job.

Here at CAM Tech, we have designers and engineers who are trained and experienced in mold making so they can maximize wire EDM’s great potential for your next project. Maximizing the advantages of using wire EDM will help you save money, time, and effort while providing high-quality products.

Though there are many advantages of using wire EDM machining for your manufacturing needs, be sure to choose an experienced company with quality machines and expert operators so you get the best possible results.

At CAM Tech, we provide quick turnaround times while maintaining a high standard of quality. Call or email to see how we can help you with your project.