Electrical discharge machining (EDM) has been around for several decades as the solution to machining materials that are resistant to traditional machining methods. Though there are different types of EDM machining, we’re going to discuss some of the advantages of Wire EDM.

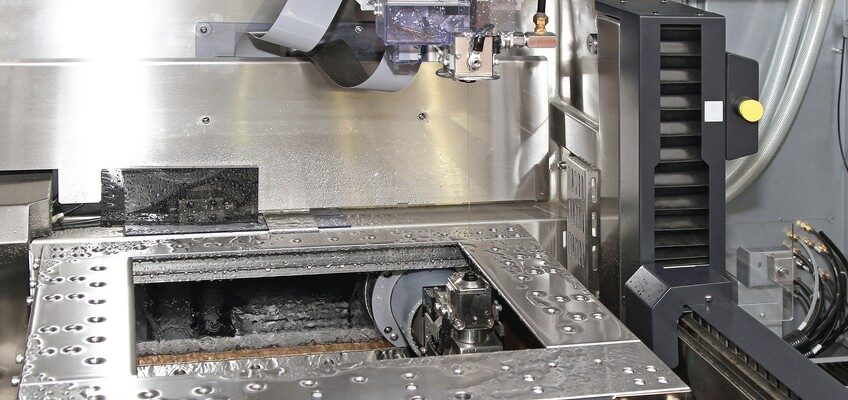

Wire EDM, also known as spark eroding or spark machining, is one of the most efficient and cost-effective ways to machine challenging electrically conductive materials whether those materials are extremely hard or very fragile. Additionally, wire EDM provides unbeatable accuracy in cutting complex shapes.

Machining hard materials can be an intense and long process. In other cutting modalities, tools need to be applied with a large amount of force to create the desired shape. In turn, this can create stress on the material and cause distortions while also rapidly wearing down the tool. Quite the opposite, wire EDM can machine hard and fragile materials without causing impacts or stress fractures.

This machining has a widespread application, from small hole drilling to automotive and aerospace components. Wire EDM machining leads to the production of more fine and smooth finishes compared to other fabrication techniques.

Wire EDM uses electrical discharges that flow throughout a fine wire, which allows for precision with even the most complex and intricate shapes. Wire EDM machining is more accurate than plasma or laser cutting. And because the process imparts no force on the materials, wire EDM machines can achieve very high tolerances which eliminate the need for additional processing. That might be the best part of Wire EDM – the final products do not need to be passed through grinding or honing.

On the topic of processing, with an experienced engineer, wire EDM projects can also be completed in a shorter amount of time. The faster a project is completed; the sooner essential parts will arrive at your door and be ready for use. Not only does this save time, but it also saves you money!

The pros of Wire EDM far outweigh any potential cons, but it is important to remember that this method can only be used on conductive materials. That means wire EDM can cut any type of metal including steel, titanium, superalloys, brass, and more. But it is not suitable for cutting plastic, stone, glass, or wood.

Though there are many advantages of using wire EDM machining for your next project, be sure to choose an experienced company with quality machines and expert operators so you get the best possible results. Whether you need prototypes or are ready for a production run, contact us at CAM Tech, Inc.