Wire Tensile Strength

Knowing an EDM (electrical discharge machining) wire’s tensile strength is important. While the wire doesn’t touch the part while cutting, it is stretched by the EDM machine’s wire drive feeding mechanism which consists of lower and upper feed contacts, roller guides, and wire tensioners.

Tension is preloaded on the wire, though it can be increased or decreased to achieve different cuts. Tensile strength is what determines whether or not a wire will endure the tension imposed on it during cutting. Wires with lower tensile strength are easier to break, while those with higher tensile strength are more difficult to break.

Low tensile strength wires cut angles easily without breaking. The good thing about such wires is that one can achieve angle cuts and tapers of up to 45-degrees by simple offsetting or displacing guides in the U-V axis. High tensile strength wires, on the other hand, can be stretched a lot more when using the U-V axis for better control of the vertical wall’s perpendicularity for a more precise cut.

When it comes to roughing, manufacturers typically state that a low wire tension allows the machine to cut much faster without the wire breaking. And they claim that skim cuts, on the other hand, require a higher tension, allowing less power and lower speeds for precision.

However, low tension wire costs more and is known for creating threading issues on the auto threader. So, here at CAM Tech, we have found a way to use high tension wire in nearly every application. This improves our turn-around time and saves you money!

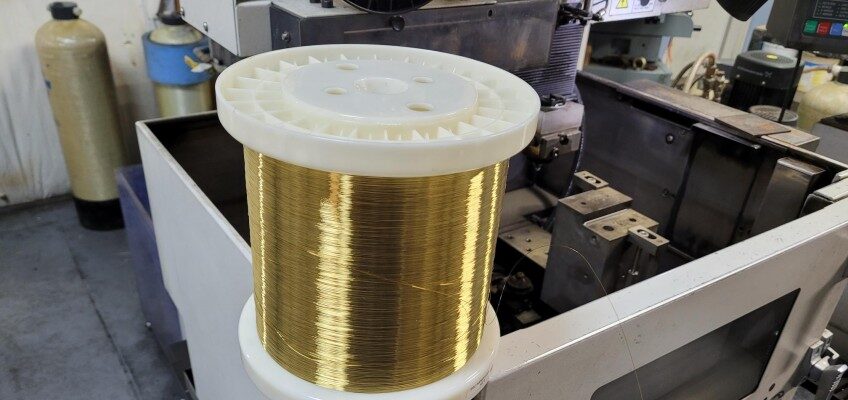

These days, electrical discharge machining wire is typically sold in 16 kg (35.2 pounds) spools. That’s about 65 hours of cutting under standard cutting conditions.

Some EDM wire manufacturers offer larger spool options (even up to 100-pound spools) for longer uninterrupted cutting times (up to 180+ hours of continuous cutting). In this scenario, a single spool can run nonstop 24/7 and will last for more than a week before it has to be changed.

Wire Availability

As with many industries, EDM service providers can be affected by supply chain issues with parts coming from overseas. Over the years, we have tested a variety of wire manufacturers and have found the best quality and price combination comes out of Vietnam. We have been able to source wire from two different suppliers.

Between COVID shutdowns, and wire sitting on container ships for months, it has been challenging to get wire on a consistent basis. Orders placed in March 2021 started delivering in October. The good news for our customers is that for more than 3 years we have been maintaining a 6-7 month wire inventory in our shop at all times. This has helped us weather the storm.

What this entire blog post means is that you have nothing to worry about! Acquiring and keeping an inventory of EDM wire of the proper tensile strength is our job! With our expertise and experience we will choose the best wire for your project to produce the best results. If you have questions, or are ready to get started, contact us at CAM Tech, Inc.