When it comes to precision cutting, two popular methods often stand out, Wire EDM (Electrical Discharge Machining) and laser cutting. Both deliver excellent results, but they work in very different ways. Choosing the right one depends on your material, design, and priorities. Let’s go over each.

What Is Wire EDM?

Wire EDM uses a thin, electrically charged wire to cut through metal. Instead of using a blade or flame, it relies on electrical sparks to melt away material. Because the wire never actually touches the surface, the process is extremely precise and leaves a clean finish.

This method is perfect for hard metals and projects that require very tight tolerances, meaning the measurements must be exact. Industries like aerospace, medical device manufacturing, and toolmaking often rely on Wire EDM because accuracy matters so much in those fields.

Wire EDM produces extremely accurate cuts, even on thick or tough materials. The finish is smooth and often requires little to no polishing afterward. Since there’s no physical pressure on the material, there’s also no risk of bending or distortion. However, the process can be slower compared to laser cutting, and it only works on conductive materials like metal.

What Is Laser Cutting?

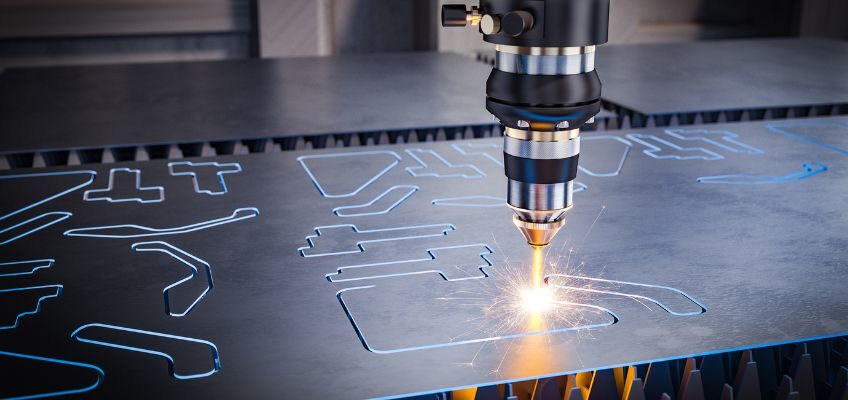

Laser cutting, on the other hand, uses a focused beam of light to melt, burn, or vaporize the material. It’s a fast and versatile process that can handle metal, wood, plastic, and more. Because it’s so quick and adaptable, laser cutting is widely used in fabrication shops, architecture, signage, and even creative art projects.

Laser cutting stands out for its speed and ability to handle many materials. It’s great for intricate designs and detailed patterns. However, because it involves heat, there can be slight distortion on thin materials, and while it’s very precise, it’s not quite as accurate as Wire EDM when working with extremely fine tolerances.

Which One Should You Choose?

If your project involves thick or hard metals and you need top-tier precision, Wire EDM is likely the better choice. It gives you accurate, burr-free edges and smooth finishes that are ideal for high-performance parts.

If your goal is to complete your project quickly or you’re working with a variety of materials, laser cutting might be the way to go. It’s faster, flexible, and great for designs that require intricate detail without the need for ultra-high precision.

Both Wire EDM and laser cutting have their strengths. The right one for your project depends on what you value most, precision or speed. If accuracy and detail are important, go with Wire EDM. If you need versatility and efficiency, laser cutting will serve you well.

For projects that demand exact measurements, flawless finishes, and professional craftsmanship, trust CAM Tech Inc. Our team specializes in Wire EDM services that deliver unmatched precision and quality. Whether you’re working on complex parts or custom components, CAM Tech has the experience and technology to bring your designs to life.

Contact us today to discuss your project and see how our Wire EDM expertise can make the difference.